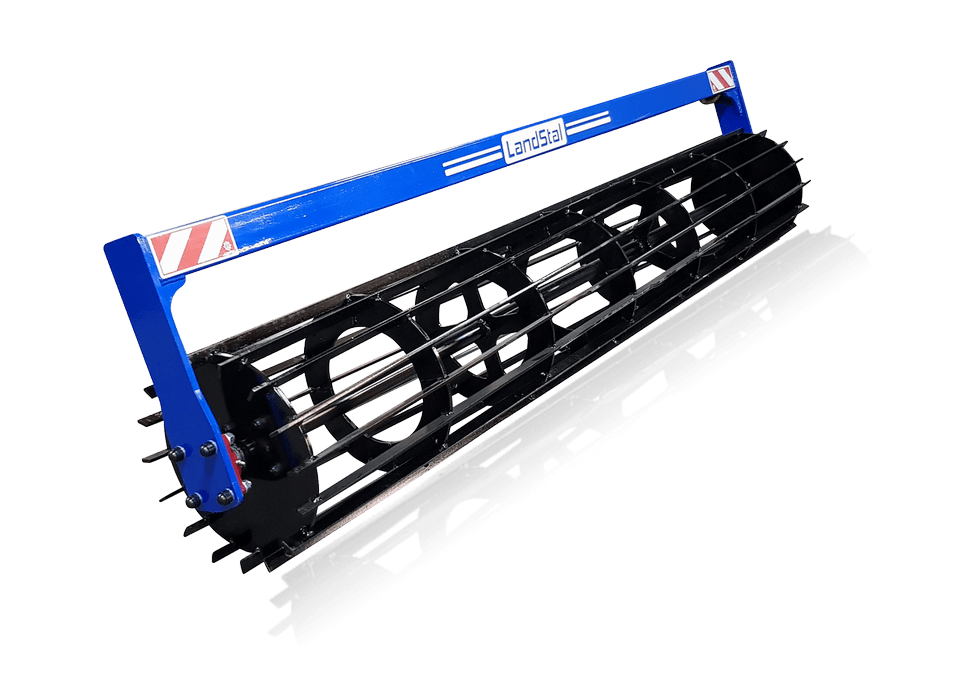

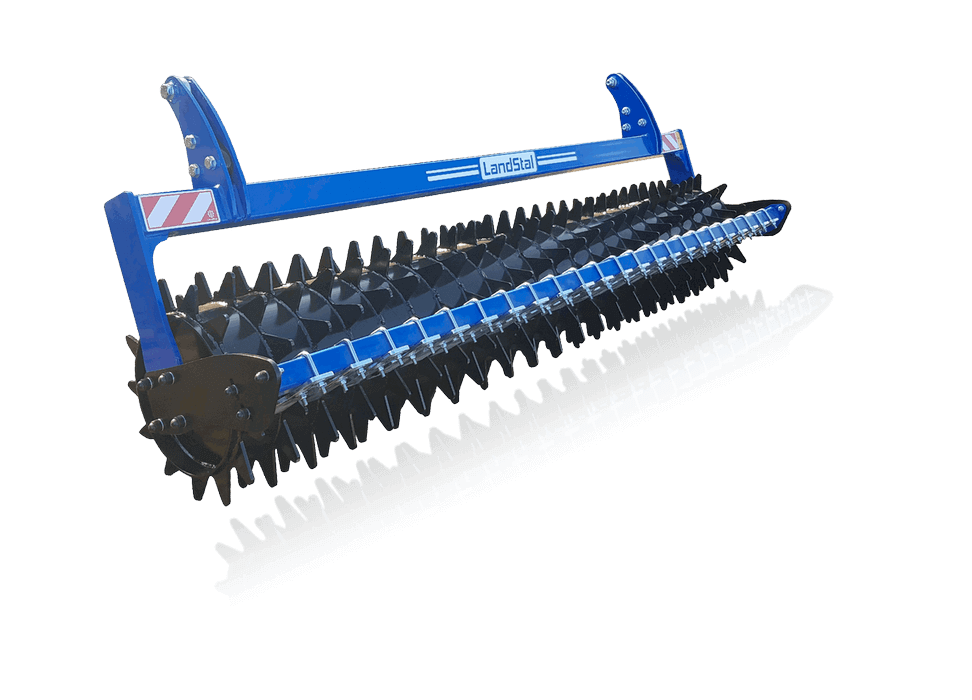

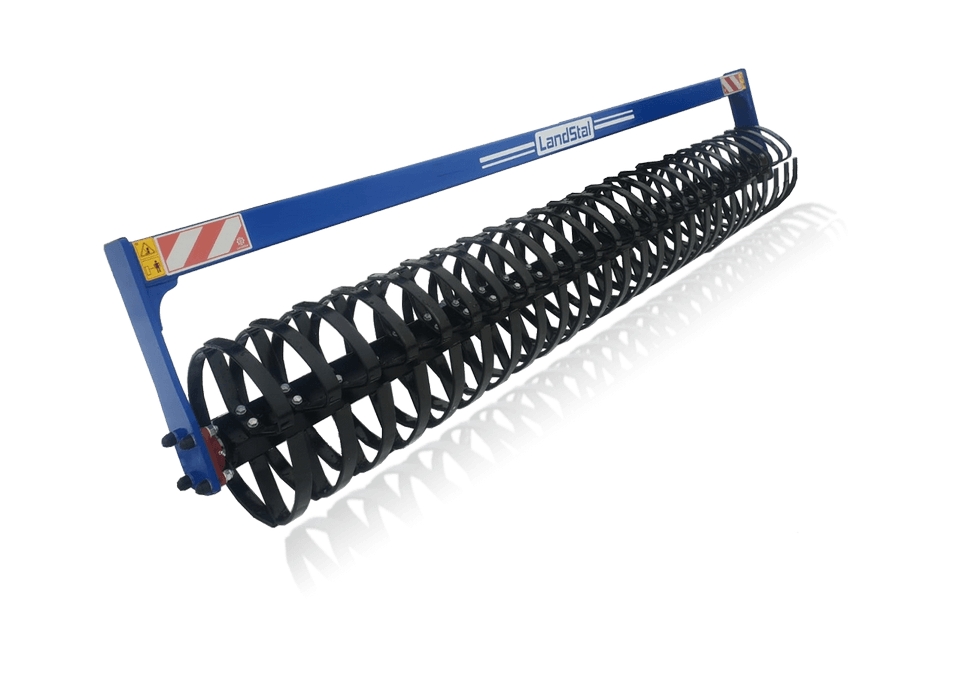

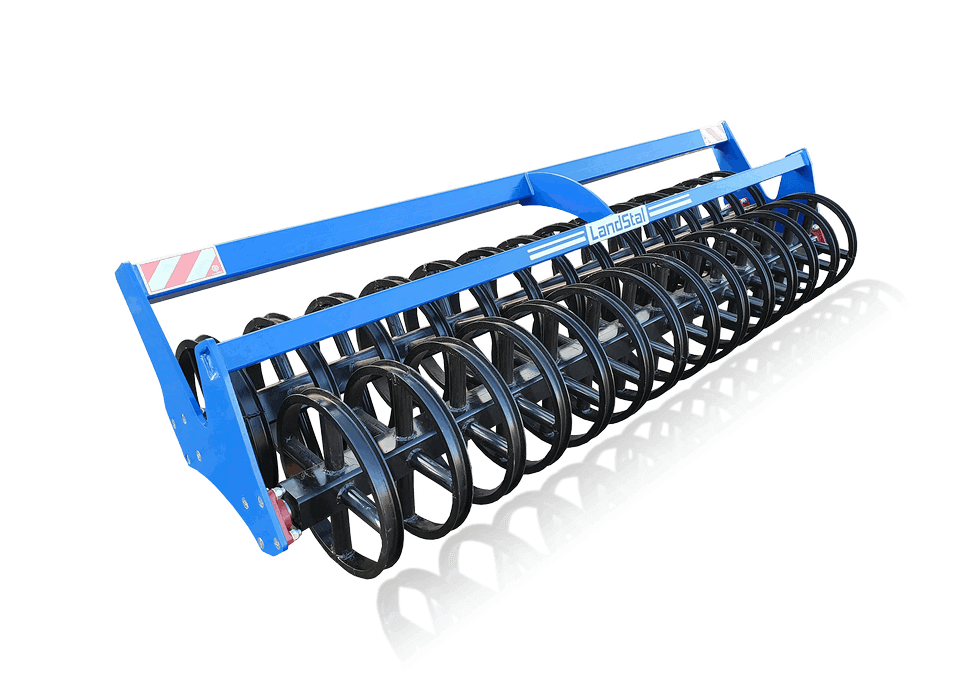

| Model | Width (m) | Weight (kg) | Count discs (pcs.) | Power demand (KM) | Efficiency (ha/h) | Maximum working depth (cm) |

|---|---|---|---|---|---|---|

| BTH 400 | 4,0 | 2500 | 32 | 100-150 | 2,9-4,2 | 14 |

| BTH 450 | 4,5 | 2800 | 36 | 130-160 | 3,1-4,9 | 14 |

| BTH 500 | 5,0 | 3160 | 40 | 140-180 | 4,1-5,9 | 14 |

| BTH 600 | 6,0 | 3600 | 48 | 170-210 | 5,0-7,0 | 14 |

* The weight is approximate and may differ from actual depending on the model and configuration.