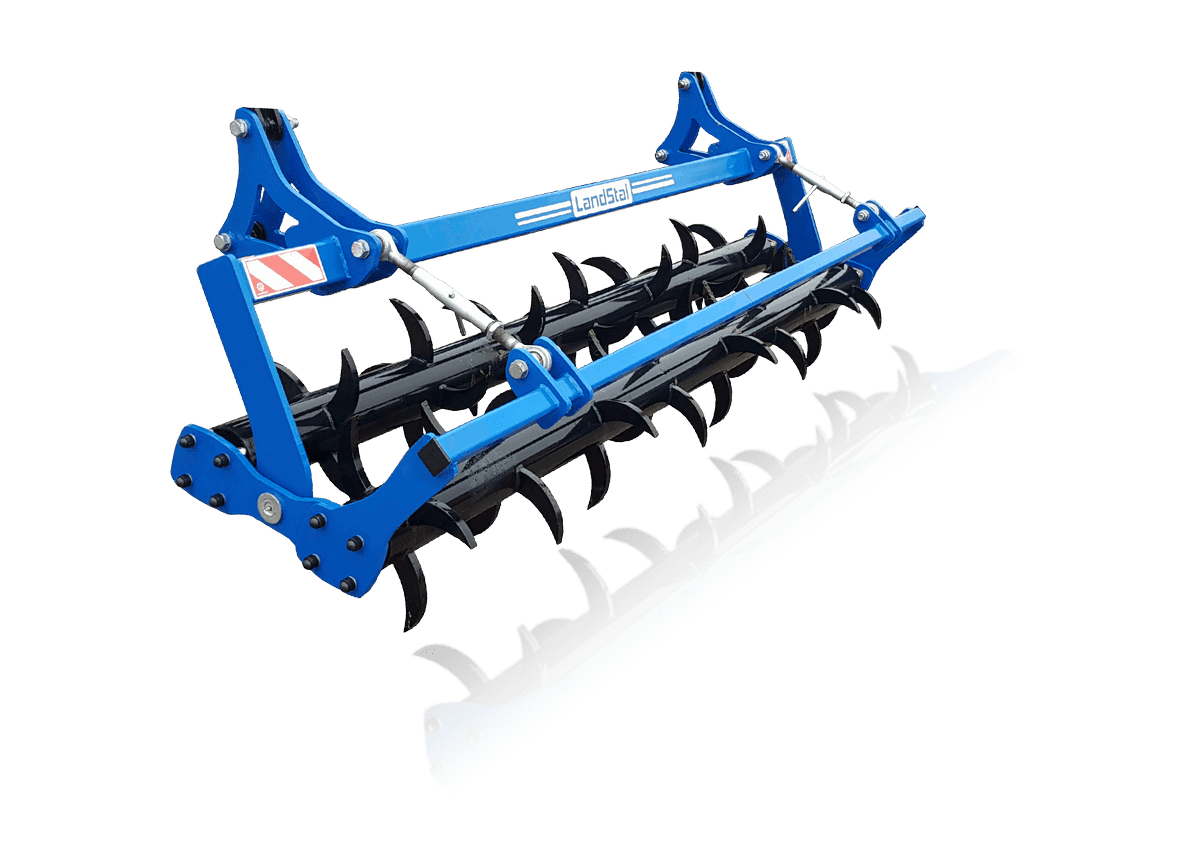

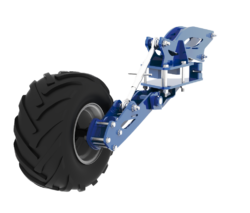

| Model | Width (m) | Weight (kg) | Count tines (pcs.) | Power demand (KM) | Efficiency (ha/h) | Maximum working depth (cm) |

Protection system |

|---|---|---|---|---|---|---|---|

| GZ 300 | 3,0 | 1000 | 4 | 110-130 | 1,6-2,5 | 55 | Bolt |

| GZ 300+ | 3,0 | 1200 | 6 | 130-150 | 1,6-2,5 | 55 | Bolt |

| GZ 400 | 4,0 | 1500 | 8 | 150-180 | 2,7-3,8 | 55 | Bolt |

*The weight is approximate and may differ from actual depending on the model and configuration.